Direct-to-Film printing

DTF, short for ‘Direct-to-Film’ is a printing technique that is gaining rapid adoption in the Textile & Apparel industry.

Designs and logos are printed on special media called ‘DTF film’ using an inkjet printer with dedicated DTF inks (heat transfer pigment ink), which is often backed up with a white ink layer.

A soluble ‘hot melt powder’ is then applied, which adheres to the wet ink layers, and acts as the glue between design and fabric.

The film then passes through a dryer unit, drying the ink and smoothing the powder layer.

The resulting direct to transfer sheet can then be heat-pressed on fabrics such as cotton, polyester, polyester blends, silk, and leather.

What is the Market Opportunity?

Apparel decoration is a highly popular and dynamic sector, where DTF technology has had a huge impact in recent years.

DTF is ideal for logos, images and labels on the front-side, back-side, sleeves and inside of T-shirts, hoodies, and work clothing.

Personalisation, such as names and numbers on sportswear further extends the usage and promotional items like caps and bags are further good usage examples.

DTF has some significant advantages over existing technologies as it can be heat-pressed on a wide range of fabrics as well as being suitable for full-colour and detailed designs, ideal for small runs whilst offering good washability*.

DTF is therefore expected to significantly increase its share in the apparel decoration segment.

Why choose Mimaki?

Mimaki is a leading manufacturer of wide-format inkjet printers for the textile and apparel industry, with a world-wide sales and service organisation.

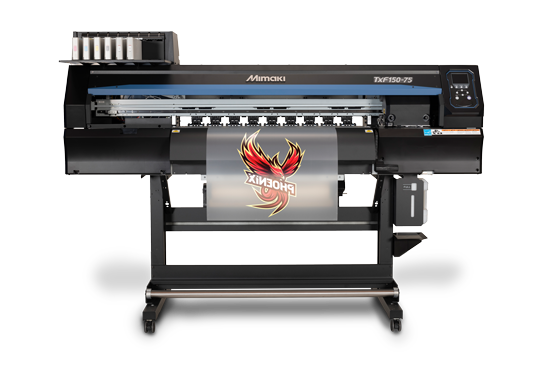

The TxF Series is Mimaki’s first DTF printer, offered with Mimaki’s genuine DTF ink and RasterLink 7 RIP software. This unique combination ensures a highly reliable and stable DTF print workflow, combined with Mimaki’s guaranteed service and after purchase support.

Other consumables and equipment, like the DTF film, hot melt adhesive powder, DTF shaker and dryer unit and heat press must be purchased separately.

Market proven technologies

The TxF Series is packed with market proven technologies, to counter common issues of currently available direct-to-film printers, like ink sedimentation and a clogged ink supply.

Mimaki DTF ink

Mimaki’s genuine DTF ink (PHT50) ensures a high and consistent ink quality, regardless of production batch or order date.

RasterLink 7

RasterLink 7 offers convenient DTF functionality such as variable data printing and white layer creation/positioning, all in a simple and user-friendly interface.

Important Recommendations

In addition to the print quality, also the quality of the DTF film and used powder, as well as the timing and temperature settings of the drying unit and heat press can make or break the ‘end-result’.

Use DTF films with a thin and uniform surface for better temperature and transfer characteristics.

Use Polyurethane hot melt powder with a diameter of around 200 microns for the best adhesion characteristics.

Although the powder can be applied manually, to guarantee a more uniform thickness, and thereby improve its transfer characteristics, use dryer units with a powder supply and shaker section (DTF shaker and dryer).

Follow the instructions of the DTF film supplier/manufacturer for the press (temperature & time) and peel settings.