DTF Printer TxF Series

Mimaki’s first DTF (Direct-to-Film) printers, packed with Mimaki technology

A safe and stable machine for your DTF print transfer sheets

INTRODUCING THE ALL NEW TxF300-75 – While both printers in the series offer the same superior Mimaki technology, the recently released TxF300-75, with 2 staggered printheads, delivers new levels of productivity with speeds up to 3x faster than the TxF150-75 (one printhead), helping to expand opportunities in the market.

Unique features

- Degassed ink packs

A common issue with current DTF printers in the market occurs when air inside the ink bottle reaches the print head, causing ejection issues.‘Air free’ ink packs strongly reduce the chance of air entering through to the ink supply and eventually the print head, thereby ensuring constant image quality.

A common issue with current DTF printers in the market occurs when air inside the ink bottle reaches the print head, causing ejection issues.‘Air free’ ink packs strongly reduce the chance of air entering through to the ink supply and eventually the print head, thereby ensuring constant image quality.

The packs are placed in eco-friendly reusable cases, which reduce environmental waste, thus increasing the overall sustainability.

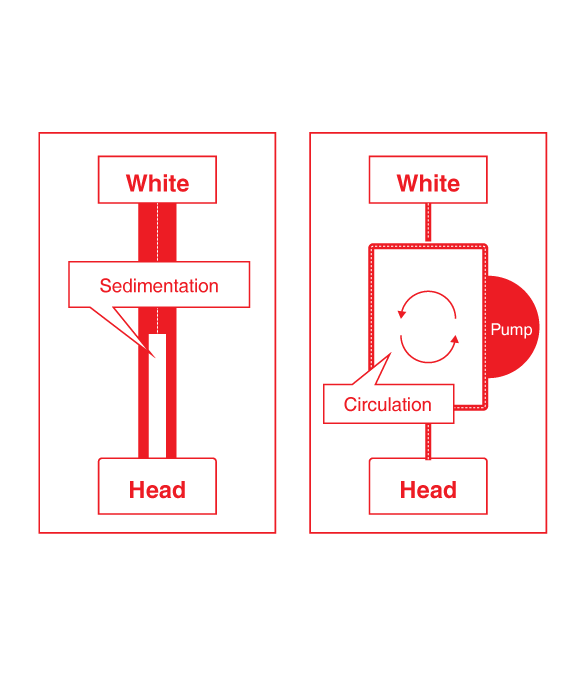

- White ink circulation

Another common issue with current DTF printers in the market is white ink clogging, causing ink supply issues.Being larger and heavier, white pigments have a higher chance to settle. Periodically circulating the ink prevents sedimentation, thereby ensuring constant ink quality and stable production.

Another common issue with current DTF printers in the market is white ink clogging, causing ink supply issues.Being larger and heavier, white pigments have a higher chance to settle. Periodically circulating the ink prevents sedimentation, thereby ensuring constant ink quality and stable production.

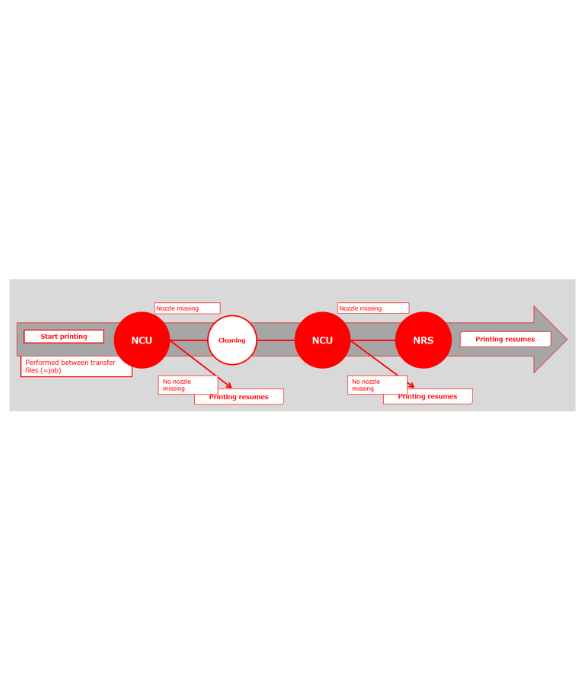

- Nozzle drop-out detection

A continuous process which checks and detects for clogged nozzles and starts a cleaning cycle to recover them.When the cleaning cycle can’t recover them, those nozzles will automatically be substituted with open nozzles to ensure constant image quality and uninterrupted production.

A continuous process which checks and detects for clogged nozzles and starts a cleaning cycle to recover them.When the cleaning cycle can’t recover them, those nozzles will automatically be substituted with open nozzles to ensure constant image quality and uninterrupted production.

- ECO PASSPORT certification

Mimaki’s PHT50 pigment ink has acquired OEKO-TEX® ECO PASSPORT certification.This is a globally accepted and independent certification system which demonstrates that our ink is suitable to print skin-friendly clothing and other textiles for end users.

Mimaki’s PHT50 pigment ink has acquired OEKO-TEX® ECO PASSPORT certification.This is a globally accepted and independent certification system which demonstrates that our ink is suitable to print skin-friendly clothing and other textiles for end users.

Designed to produce DTF transfer sheets

for the wear printing market

Heat transfer pigment ink

The TxF Series uses Mimaki’s genuine DTF ink PHT50.

PHT50 is a dedicated ink to print directly on DTF-specific film. It is then hot-melt powdered and heat-treated to create transfer sheets.

The ink, available in 5 colours (CMYK + White), offers high density and vivid colours while printing the smallest details.

Mimaki’s guaranteed ink quality standards, in combination with the available colour profiles for the RIP, ensures a constant and predictable image quality for the long run.

For even more confidence

our inks are OEKO-TEX® certified

Mimaki inks PHT50 are OEKO-TEX® certified. ECO PASSPORT by OEKO-TEX® is a mechanism by which textile chemical suppliers demonstrate that their products are suitable to print skin-friendly clothing and other textiles for end users.

This certificate therefore constitutes an important decision-making element when purchasing inks for textile production.

This printer is packed with Mimaki Core Technologies that maximises production stability and image quality at all times. Refer to the below list of core technologies that are included in the TxF Series.

For continued productivity

- Nozzle Check Unit (NCU), to detect missing nozzles

- Nozzle Recovery System (NRS), to replace missing nozzles

- Automatic Cleaning Function, to keep the print head clean

- Mimaki Circulation Technology (MCT), preventing white ink sedimentation

- Uninterrupted Ink Supply System (UISS), for uninterrupted ink supply

For quality printing

- Mimaki Advanced Pass System (MAPS4), to reduce banding

- Waveform Control (WFC), for best possible image sharpness

- Variable Dots Technology (VDT), for smoother gradations

- Mimaki Fine Diffusion (MFD), for smoother colours

- Mimaki Intelligent Heater (MIH), for consistent image quality

Combine your TxF Series printer with:

Inline 800 – DTF Powder Shaker Cure Unit – by Adkins

Matching the maximum print width of the TxF Series printers, this powerful powder shaker cure unit ensures the even distribution of powder across DTF film rolls of all sizes up to 80cm in width.

Among the main advantages is low energy consumption during operation. Also, built-in filtration, which means no (external) extraction is required.

Futhermore, media supply and powder applicator sensors (allowing the device to stop feeding/applying powder when there is no film and/or powder). There is also media suction control with preheat settings. Print-ready cooling fans let you get started immediately.

| Model | TxF300-75 | TxF150-75 |

| Print head | 2 heads (staggered) | On-demand piezo head |

| Print resolution | 720dpi, 1,440dpi | |

| Ink type/colour | Heat transfer pigment ink PHT50 (C, M, Y, K, W) | |

| Ink capacity | 600ml ink pack x 1 (500 ml for white only x 4) | 600ml ink pack x 1 (500 ml for white only x 2) |

| Circulation function | Available only for white ink | |

| Maximum print width | 800mm (31.5 in) | |

| Media maximum width | 810mm (31.9 in) | |

| Media thickness | 1.0mm or less | |

| Roll weight | 45kg (99.2lb) or less | |

| Interface | Ethernet 1000 BASE-T / USB2.0 Hi-speed | |

| Power specifications | Main unit: Single-phase AC100-120 / 200-240±10%, 50/60Hz±Hz x 1 | |

| Power consumption | 100V system: 0.9kW or less, 200V system: 1.2kW or less | |

| Certifications | VCCI class A, FCC class A, ETL IEC 62368-1, CE Marking (EMC, Low voltage, Machinery directive, and RoHS), CB, REACH, Energy Star, RCM, KC | |

| Dimension (WxDxH) | 1,965 x 700 x 1,392 (77.4 x 27.6 x 54.8in) | |

| Weight | 126kg (277.8lb) | |

Software RIP

Mimaki’s software RIP, which combines usability and high performance, comes with convenient DTF functions like variable data printing and white layer creation.

RasterLink7

PHT50

Heat transfer pigment ink

Dedicated ink to print directly on DTF-specific film, then hot-melt powdered and heat-treated to create a sheet layer for transfer.

Packaging

W (White): 500 ml ink pack

Colour

Ink type

Learn more about Mimaki’s first DTF printer

Request a demonstration

TxF150-75

TxF300-75