– Steve Cory, Founder Objex Unlimited, outlines his thoughts on previous and current trends in the 3D Printing market, and how he expects the market to develop over the coming years

– The first person in Canada to receive a Mimaki 3DUJ-2207, Steve Cory now owns two 3DUJ-553 printers, and has gone on to become the Canadian distributor of Mimaki 3D printers

How was 3D printing in full colour received by the 3D printing industry?

Printing in full colour was not initially a priority for those using 3D printing. However, with the introduction of the Mimaki 3DUJ series, the market has shifted, and businesses are becoming more innovative in their use of the technology. This in turn is driving 3D printing use to new markets and applications, as full colour opens up new opportunities. Companies who previously didn’t see the need to print in colour are now seeing the benefits of it, and many companies who previously used more traditional methods, such as injection moulding, are turning to 3D printing. There’s also a growing new market of businesses born into colour 3D printing, such as mine with Objex Unlimited. We started in 2011, with the objective of 3D printing in full colour and create models, mainly for art purposes.

Is colour growing in importance in the 3D printing industry?

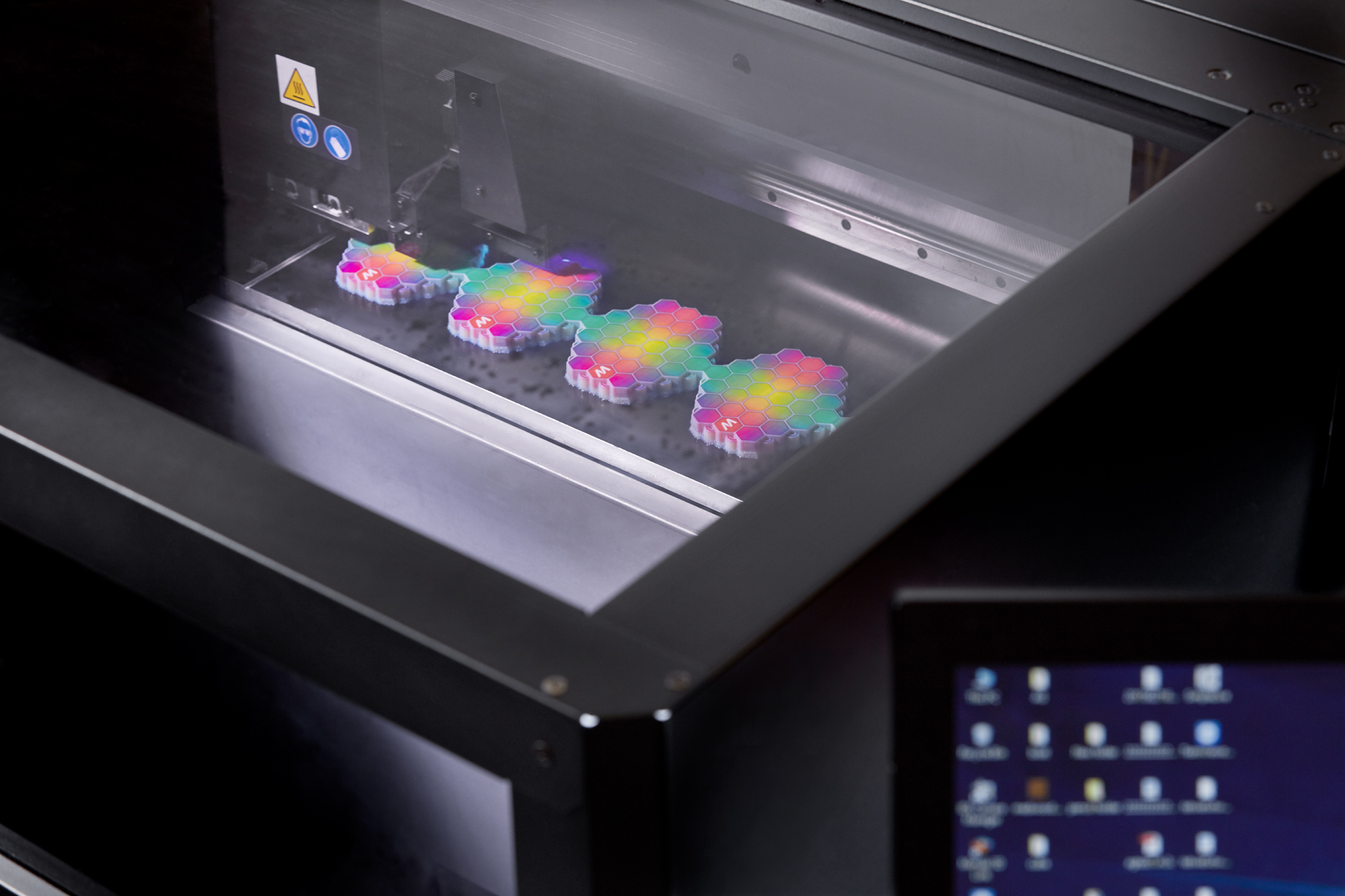

I would say high quality colour is bringing more people to the industry. Previously, Objex Unlimited offered engineering, architectural and archaeological model making, but now we are also seeing customers in marketing, a growing demand for figurines from a diverse customer base, and many companies requesting 3D printed models. For marketing, 3D printing can speed up product development, and save a lot of time in producing prototypes. The gaming industry is an unexpectedly large part of our customer base. We produce figurines of in-game characters, as well as people’s own avatars. Customers want these in full colour, and printing in colour saves time and produces better results than painting them after printing. We can also achieve better colour accuracy with printing in colour, as the Mimaki 3DUJ series can print over 10 million colours and has incredible screen to print colour accuracy, allowing us to achieve the desired colour easily and without testing.

How important is clear resin in colour printing?

This depends on the applications you are wishing to produce, but clear resin is important for a variety of needs. The most obvious is to create a clear object, such as a car windshield. However, clear resin is also helpful in protecting fine details, so that these are reinforced, preventing post-print breakage and ensuring the piece will last longer. Clear resins can be mixed with colour resins to create a semi-translucent object which we often use for art pieces. Another use is as a gloss finish, as it can be used to encase details you want to have a completely translucent shell, which ensures the detail inside is clearly visible.

How important are flexible and bio-compatible materials?

Unfortunately, there’s no one machine that can work with every material and solves every AM issue. If you want to make beautiful full colour parts easily and cost effectively, the Mimaki 3DUJ series is great. However, if you want to start making bio-compatible, flexible colour prototypes with multiple materials, different properties and all the cost, effort, and challenges those entail, you will have to look at other machines. 3D printing is a fairly new technology, and these issues will be addressed in years to come, but with the current machines available, you need to choose between flexible or bio-compatible materials and colour accurate, vibrant prints. It’s a common misconception in the market that you can have one machine that does it all, and especially when you want to keep investment low, it’s just not possible yet.

What do companies need to consider before investing in a 3D printer?

The main consideration should be what applications they are looking to use the machine for, and finding a printer that meets those needs, while also keeping within your budget. Ongoing costs should be considered, so finding a printer which produces minimal waste and is cost-effective to run is important. However, the factor I think most companies do not consider, is while printing is easy with the right printer, designing the part to be printed is not. You need to have a designer experienced in digital design specifically for 3D printing as the processes and software are very different to other kinds of digital design.

What capabilities should companies look for in a colour 3D Printer?

Again, it does depend on the applications you’re looking to use the printer for, as different printers will prioritise different capabilities. However, colour consistency and screen to print accuracy are important for any colour application, as the model needs to replicate what you see on the screen before printing. In order to create complex and challenging parts, the material needs to be durable and workable. I’ve found that the water-soluble support material provided with the Mimaki 3DUJ series also helps with this, as it means the part can be gently removed from its supports with minimal chance for damage. To fulfil large orders and volumes, the printer needs to be run regularly, so it will need to be reliable, and able to handle long run-times.

What are some typical run-times you’d expect to see in any given week?

We run our machines as often as possible, according to the machine’s capabilities. A typical print is anywhere between one to one hundred hours, but it depends on the size of the part you’re printing. The longest print I’ve done on our Mimaki 3DUJ-553 is 160 hours for one part, but we also do shorter one hour prints frequently with it. With our first Mimaki, we ran it for 5,600 hours out of the 8,000 available in the year, without an issue or failure. Recently, we had a busy week where we ran 24 hour prints on each of our 3DUJ-553s, we ran seven prints back-to-back on each machine without any problems, failures and minimal downtime. The only downtime necessary is to take the part out and clean the machine, which takes around three minutes.

What does the future hold for the 3D Printing Industry?

As 3D printing is a new technology, it is still rapidly evolving. Materials are still being developed, and I predict an increase in the variety of materials available, which will expand the capabilities offered. In future, we won’t have to choose between full colour and flexible, biocompatible materials, as a solution offering all such qualities will be available. I also see an increase in the speed and efficiency of these machines, making them more suitable for industrial use. On the design side of things, software will advance, and it will be easier to design parts to print. An exciting development already beginning is the use of VR to mould parts out of virtual clay, which I can see becoming more popular. In terms of businesses and customers adopting 3D printing, with high quality printers at such accessible prices, like the Mimaki 3DUJ series, adoption of the technology and popularity of 3D printed products will continue to increase.