WFC | Waveform Control

WFC automatically changes the signal to the print head when print conditions change and ensures consistent image quality. Mimaki is programming its own signals (waveform), based on print speed, resolution and humidity, to guarantee the maximum output quality at any print condition. Each time these conditions change, WFC will automatically change to the optimum waveform, achieving the highest image quality at any print speed.

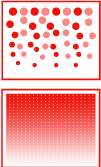

The advantage of WFC explained

WFC applied

WFC changes the waveform when print conditions change, achieving a consistent and highest possible image sharpness at any time.

WFC not applied

Using the ‘standard’ waveform, provided by the manufacturer of the print head – at any condition – will result in a more grainy and less sharp image. The image quality may differ between print runs.